24.9.2023 – Saturday – From Bitez the distance to Gumuslik is 15 miles. We were happy to see that there was a free berth on the T dock where water and electricity are included in the exaggerated price. On the first try the anchor did not hold and we had to go out and try again, this time successfully. On the dock we were met by Emet, perhaps the harbor master who immediately informed us that there is (again) a break in the water service. “Maybe later in the evening or tomorrow morning”.

Yoshi and Irit came in the afternoon and we had a really good meal in the evening.

25.9.2023 – Sunday – We are actually on the way north to Teos marina, where we would lift the boat onto the hard for the winter. First stop is Cukurcuk, 19 miles away. The girls had a nice idea of looking for a stop on the way to do some swimming. We found a small bay on the northwest of the bay of Yalikavak, where four big motor yacht were at anchor.

Going on close to twelve noon a westerly wind came and we could pleasantly sail to destination. We anchored and a delegation, Irit and Miki, was sent to shore to investigate the “simple restaurant” appearing in the guide. The owner, who seemed to be German or a Turk who lived in Germany for a long time and had an interesting appearance, let us understand that the place was far below our expectations.

So back to the boat, where Gili with Irit as a sou-chef, worked for hours to prepare a very good meal: Zukini pie, Moussaka and arugula salad and each of us had his favorite drink.

26.9.2023 – Tuesday – On the way to our day’s target we stopped at a bay called in the guide Mavisehir and on Navionics Seddef. It is not the best place to anchor as the bottom is weed and rocks but we found a spot that was good for a short stay and went for a swim. Then on through a mass of fish farms to St. Nikolau, southeast of port St. Paul. St. Nik is much nicer than its neighbor. One has to be careful as the bottom comes up to 2 meters and less in places.

We had the bay for ourselves; good feeling.

27.9.2023 – Wednesday – With no suitable bay for a swim-stop on the way to Kusadai we decided to have our mid-way break in St. Nikolau. We were greeted by a nice heron sitting on a rock.

taken with a long lens

A visit on shore with the ladies gave Irit the opportunity to take our picture.

Miki, why the strange face?

A short swim to check the passage between the island and the mainland and we were on our way to Kusadasi. Entering the marina we were led to a berth opposite the one we held last time, that is close to the office, the showers and toilets and the exit from the marina.

In the evening as we went out for dinner we could see lightnings far to the south. None of us felt that had any relevance to us, but a short time after we came back drops of rain turned very quickly to heavy rain. We were lucky to be on time to close all hatches. The storm lasted about ninety minutes and it was peace and quiet once again.

This was the last day for Yoshi and Irit on the boat; tomorrow they will fly back to Israel.

28.9.2023 – Thursday – Our plan is to reach Teos marina on Saturday for the lifting out next Monday, so we had two days we could find bays on the way. Today we would go to an anchorage near Kormen island, a rocky one almost connected to the cape after which one turns to Teos. The sea was flat and oily; we crossed the courses of three fishing trawlers and had to maneuver between them.

We entered the bay with Gili on the bow watching out for a wreck reported in it.

The tip of Kormen on the left

We swam around the bay and were surprised by the phenomenon of air or other gas bubbles coming out of the bottom in many places. The guide tells about hot springs in the bay and that might be the explanation, although I came out of that swim practically freezing.

29.9.2023 – Friday – The light of the early morning painted the Kormen island with beautiful colors. The yacht in the picture came just a few minutes after we did.

We took our time in the anchorage paddling the SUP and swimming. At 1130, just as we raised the anchor the serenity of the bay was shattered by three tourists noisy gulets. We rounded the island and turned north to Teos limani, 1.6 miles to Teos marina as the crow flies and 4.5 miles around land. The ruins of the old city of Teos are near the anchorage and of course we walked there to see the standard, but always interesting Theater, Agora and a sanctuary for Augustus.

30.9.2023 – Saturday – It took an hour to reach Teos marina, motoring against a rising northerly wind. Teos is a big one, I downloaded the picture from their site.

Once in the marina the marineros guided us into a berth near the basin from which they would lift us up. Near the boatyard, far from everything else in the marina, but that’s only until Monday.

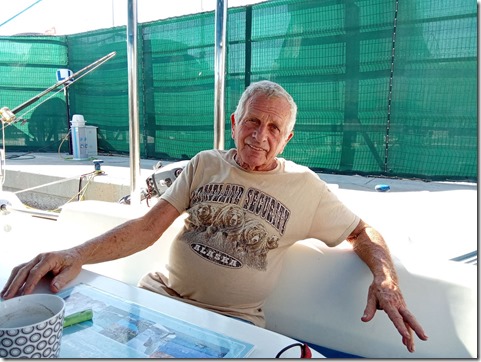

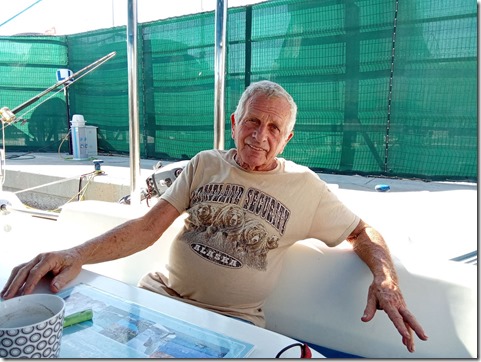

Some of my friends told me about an Israeli yachtsman living here for many years. I called him and he came for a visit.

c

c

Gideon Tur knows the village and the marina people well. He has a 16 meters aluminum yacht which he decided to keep in a boatyard in Chios, Greece , very close to his abode, where the price is half of what they wanted in Teos. Had we known about that option before…

After I told him that I had quite a few maintenance jobs I wanted to accomplish during the winter he recommended a yacht service company called Rodos which he knew well and took me to meet its owner.

Saadik seems to be a nice guy; he does not speak good English, so he suggested that on Monday I will meet his son, who has better English to talk about our needs.

1.10.2023 – Sunday – The day before the boat would be lifted to the hardstand was dedicated to cleaning, Gili doing most of the work. In the afternoon we went to the old part of the town which is actually called Sigacik and pronounced Siaachik. There was a big bazar with a lot of people meandering between shops and eateries, especially those selling sweets.

Gili was hoping to find bananas in the veg market but there were none.

She finally found them in the Migros supermarket near the marina. We had a simple dinner and went back to the boat. On the way Gili saw one of the bicycles the marina scatters for the free use of the people.

“I want to ride it” she said and in her stubbornness refused to listen to her husband who was against her idea. “It is ages since you rode one” I said. She tried to mount the bike and even before she started moving she fell down, hurting a knee, a hand and the top of head. Yachties from boats nearby rushed to help offering ice-packs, water and sympathy. She recovered quite quickly and limped to the boat.

2.10.2023 – Monday – Lift up day! Strong wind in the morning, more than 20 knots. I was a bit worried but the marina guys came on two dinghies and helped us go into the lifting basin.

So ends our 2023 sailing season. The plan is to come back on the last week of April next year.

Until then – unless I have an interesting story to tell – Adios from Gili and on the way back home.